Colnago C60

-

Livelo has one brand new C60 frame-set available for sale in size 48s (equivalent to a size 51 or small in major brand sizing).

The colour is Italia gloss, the same as the frame pictured above.

The retail price for this frame: AUD$6,234.94 (frame-set + seat post)

Contact us ASAP to secure one of the worlds most desirable bikes at a truely great price of AUD$3,999. The bike is still in original box and bubble-wrap having never been built up.

The Colnago C60 frame-set includes, frame, fork, headset and seat post.

NOT SURE HOW TO FIT OUT YOUR NEW C60 FRAME-SET?

FEATURES

The latest iteration of the classic C series (replacing the C-59 in the 2015 Colnago line-up) debuts a range of technical innovations including a new bottom bracket standard, tube shapes, dropouts, chain and seat stays. The result is a contemporary masterpiece of Italian design.

HEADTUBE

The most striking difference between the C59 and C60 is the new tube shapes and its matching shaped lugs.

The main tubes are shaped in the famous star design of the Master tubes the full length of the tubes, with no round cross section where the tubes meet the lugs. This is a first for Colnago. Lateral stiffness of the entire front triangle will increase. At the same time, the impacting forces during a rough ride will be better distributed, ensure a higher impact resistance. It may look simple, but achieving the shaping of the head-tube in this way is extremely difficult. Tubes and head tube lugs must be manufactured with paramount precision and tolerance.

As a direct result of this technical improvement, the vertical wall found in the C59 was able to be eliminated, further reducing weight while adding comfort. This feature, unique to the C59, was a limiting factor in the design and manufacturing process. The full length star tube on the C60, by comparison, allows better control of the wall thickness and lamination of the entire length of the tube. This is a huge step forward regarding strength, reliability and comfort.

BOTTOM BRACKET

The heart of the new C60 is the bottom bracket. The dimensions of this masterpiece, especially when compared to that of the C59, have been created to ensure the ultimate in lateral stiffness. The star-shaped tubing inserts provide more stiffness and a better distribution of stress. This allows for significantly reduced wall thickness. This particular section of the tubing has required a considerable study of the coupling tolerances, to ensure a coupling of tube (male) and lug (female) at the highest precision and tolerances. The system of internal cable routing is now an integral part of bottom bracket junction, forming two structural ribs that add strength to this most critical area of the frame.

DOWNTUBE

The second major difference between the C59 and the C60 is the new oversized downtube. The new shape of the bottom bracket allows for the use of a much large tube diameter, thus greatly increasing lateral stiffness.

With a square section of approximately 66x52mm (the C59 was only about 44mm) this tube represents the largest tube ever produced by Colnago. This increase leads directly to more efficiency, while at the same time reducing weight without sacrificing comfort.

Like the top tube, the star-shaped profile of the downtube runs the full length of the tube as it enters the lug, better distributing negative forces from the road surface. This tube profile improves lateral stiffness and efficiency, reduces weight and increases comfort.

SEAT TUBE

The C60 does not use a round seat tube in conjunction with star tubes and lug technology. This is another first for Colnago.

In favour of a round tube shape, the seat tube becomes strongly asymmetric as it reaches and enters the bottom bracket lug.

Due to the space required for the front derailleur, it is not possible to exploit the full width of the bottom bracket shell in the seat tube at this juncture. The solution is to use an asymmetric tube, with a width of 30mm on the left side and 21.5mm on the right half of the tube, for a total width of 51.5mm (for comparison, the seat tube of the C59 is only 34.9 mm).

To further maximize lateral stiffness and quick response to handling input preferred by Colnago’s professional racers, as well as more dynamic road performance, the C60 continues to use a 31.6 mm seat post.

Despite the dramatic increase in size, the weight of the C60 seattube is actually lower than that of the C59. This is the result of uncompromised design, material and construction methods.

ONE PIECE DROPOUTS

Another new feature introduced with C60 are the forged, CNC-machined one-piece dropouts. With the C60, Colnago has worked hard to make the connection between the frame and the rear wheel a true masterpiece.

Colnago has always been proponents of aluminum dropouts for strength and reliability. The new C60 dropouts weigh less than many products made of carbon fiber, but with absolutely incomparable stiffness and strength.

The three dimensional design in particular helps the dropout maintain lateral rigidity in even in the most demanding situations. This increased stiffness will help also in the event of a crash – where the newly designed inbound derailleur hanger will more consistently break rather than the dropout itself.

Colnago has paid attention to the smallest details on the dropouts, such as the milling on the drive-side dropout to cleanly route the cable of the electronic groupsets with no interference with the quick release lever during wheel changes.

UCI APPROVED

This frame is approved by the International Cycling Union and can be used in all races recognised by the UCI.

PAINTING

Colnago C60 frames painting, individually spraypainted in Italy one by one; every frame is unique!

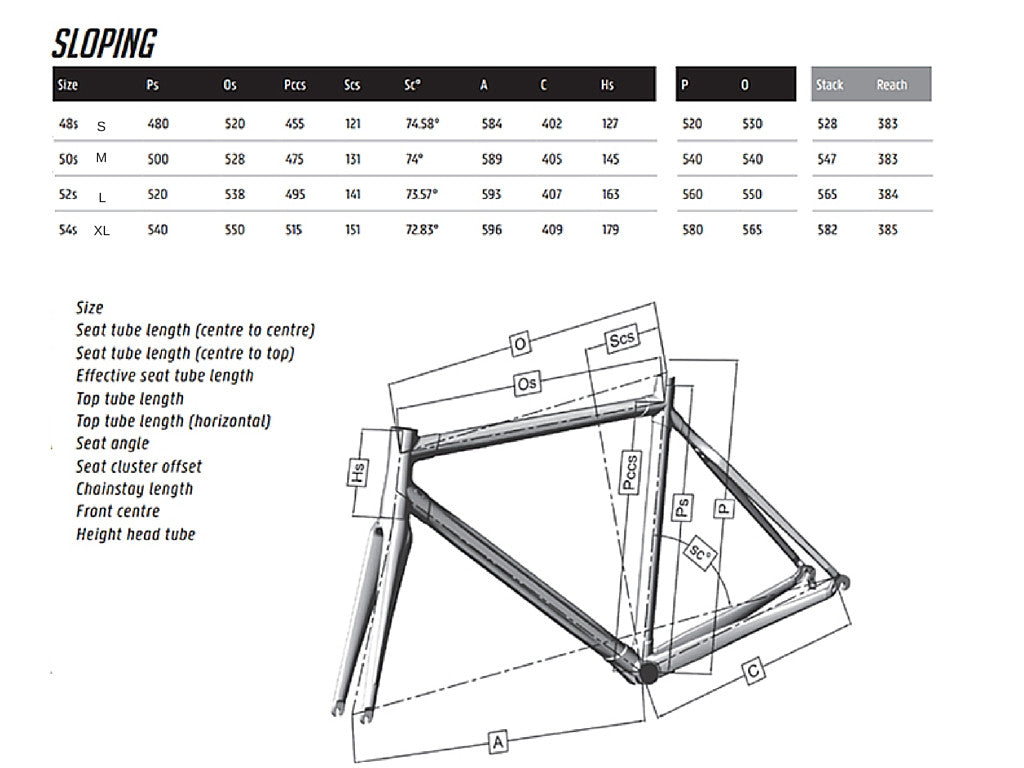

GEOMETRY

ABOUT THE MANUFACTURER - COLNAGO

Colnago Ernesto & C. S.r.l. or Colnago is a manufacturer of high-end road-racing bicycles founded by Ernesto Colnago in 1954 near Milano in Cambiago, Italy.

Instead of following his family's farming business, Ernesto Colnago chose to work in the cycle trade, apprenticing first with Gloria Bicycles at 13, subsequently taking up road racing.

After a bad crash ended his racing career, he began subcontracting for Gloria, opened his own shop (1954) and built his first frames the same year. Much in demand as a racing mechanic, he was second mechanic on the Nivea team Giro d'Italia under Faliero Masi in 1955, eventually being employed as head mechanic for the Molteni team of Belgian cycling legend Eddy Merckx.

The company first became known for high quality steel framed bicycles, and later as one of the more creative cycling manufacturers responsible for innovations in design and experimentation with new and diverse materials including carbon fiber, now a mainstay of modern bicycle construction.